carbon brushes

With almost a hundred years of experience in production of carbon brushes we well understand the significance of carbon brush efficiency in performance of the entire machine. Our brushes are designed and manufactured to maximally support:

- optimal machine operating parameters

- reduction of maintenance and repair activities

- reduction of machine operating costs

we use a variety of over seventy brush materials

The selection includes brush grades of our own production as well as Mersen brush grades. Our specialists determine the most suitable material through analysis of currents and operating conditions involved. With such a large selection of brush grades, we are able to adapt the brush not only to any electric current environment, but also to difficult working conditions (high or low humidity and temperature, dust, gas vapours, etc.).

offer requests and orders

Based on information from the customer, our technical team selects or designs a brush best suited to its working environment. The design is then manufactured by experienced staff in accordance with our strict quality norms and ISO standards.

Please provide the following information:

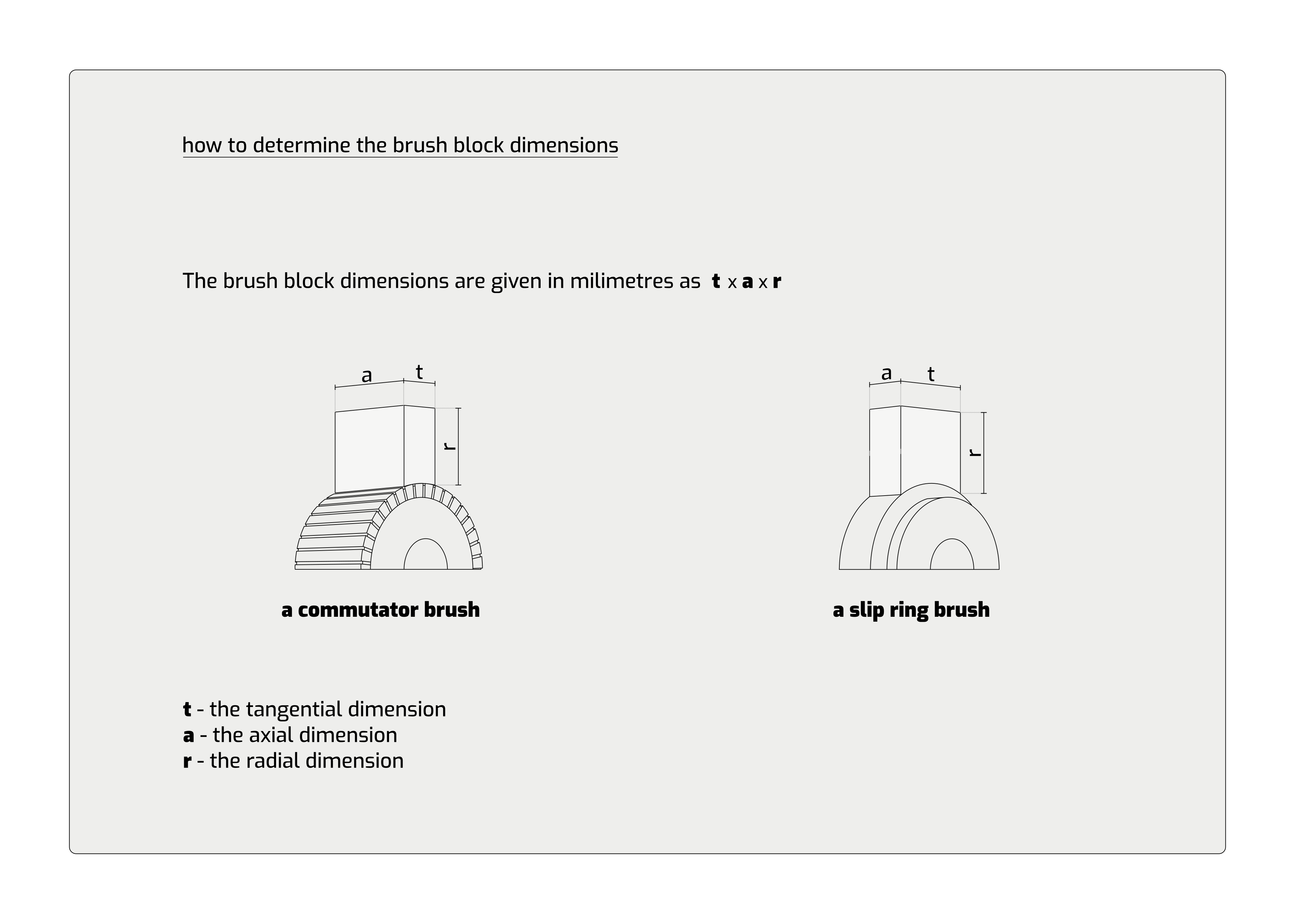

1. txaxr - brush block size

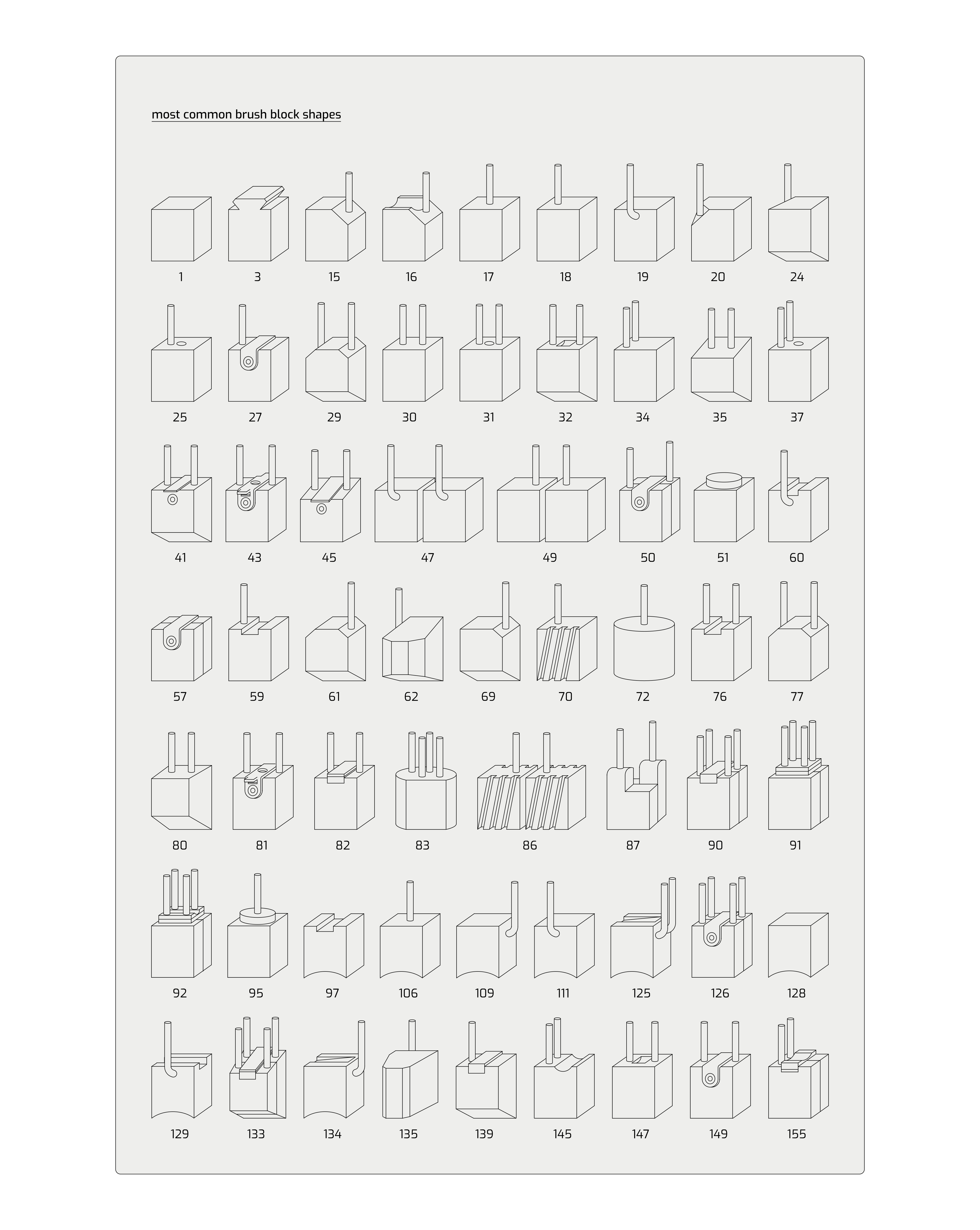

2. brush block shape

or a technical drawing / photos of the brush

3. brush grade

or application of the machine and photo of its rating plate

[ rated voltage (V), rotations per minute (rpm), power (kW), current (A)]

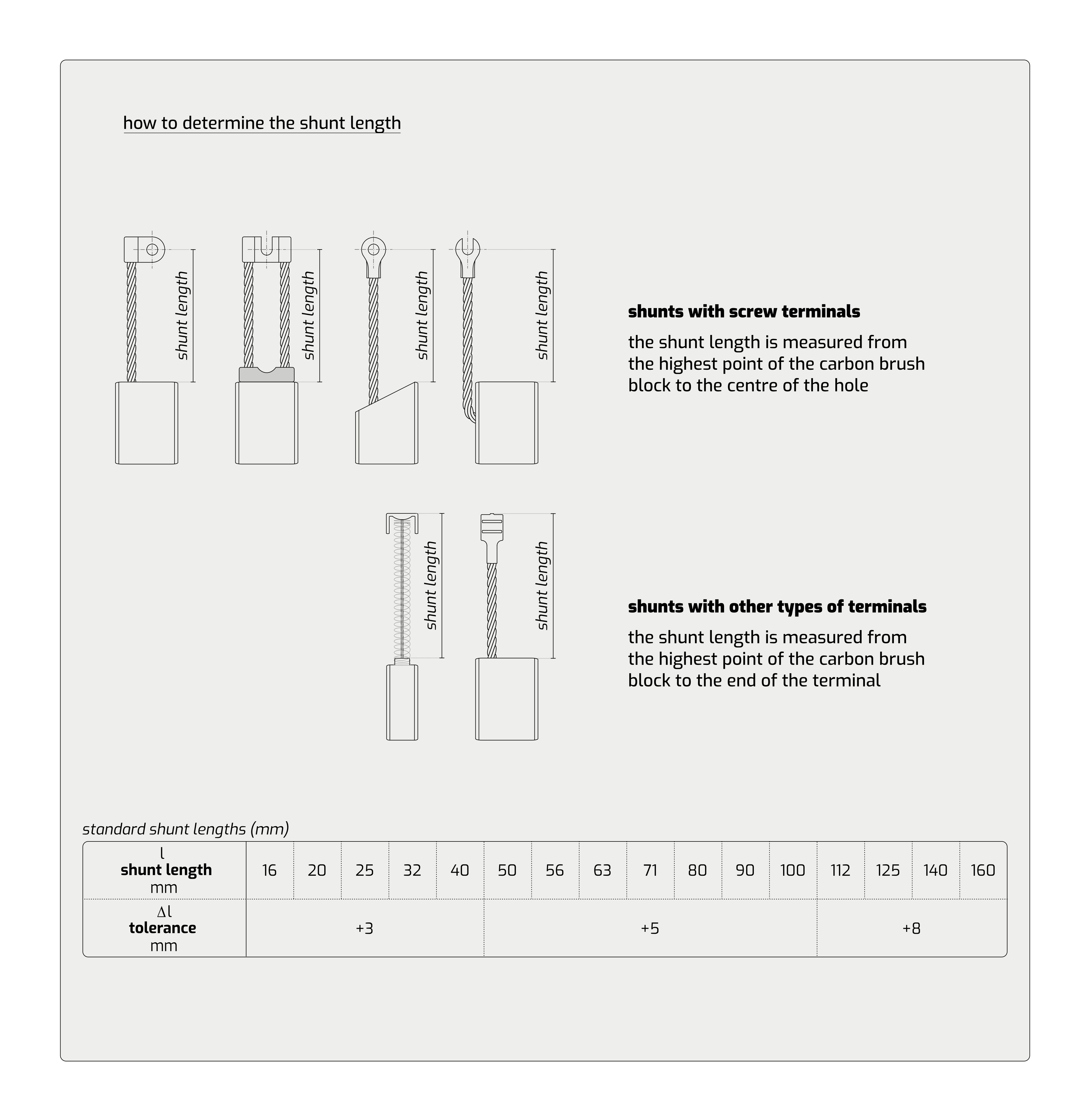

4. shunt length and if insulating sleeve is present

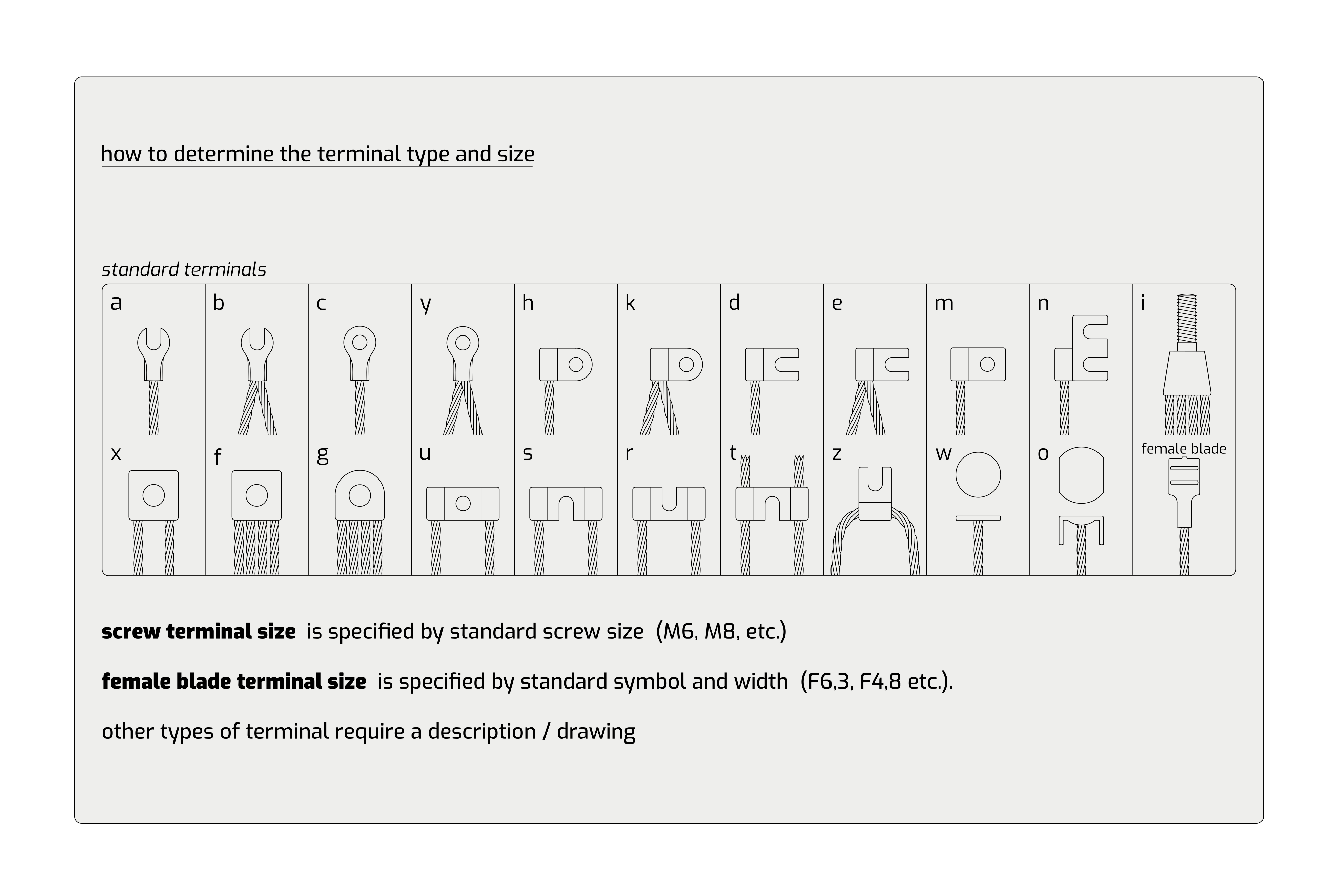

5. type and size of the terminal

We can also manufacture a carbon brush according to a sample provided by the customer.